SPECIALTY PROJECTS

New Jersey Specialty Projects

South Jersey Gas

Added a public CNG Station to petroleum fuels/convenience store; with an excellent location, adjacent to an interstate highway and warehouses complexes, lots of volumes. Duplex 450 SCFM (total 900 SCFM) 200 HP compressors, inlet gas dryer, storage system, priority control, two (2) dual hose dispensers, and a backup generator.

Pennsylvania Specialty Projects

Mack Truck Macungie, PA

2005 Mack Truck needed a solution to fill CNG cylinder pods, which were utilized on the base frame of the truck’s chassis while still on their production line. This allowed the trucks to comply with dynamometer testing before being upfitted with a body & cylinder package per the customer’s specifications. This pilot program grew in 2012 to the next phase, which required a fast-fill CNG system due to increased demand for CNG trucks. This is when we packaged a refurbished simplex compressor, priority & sequential panel, and stacked ASMEs.

Click on any photo to see a large slideshow.

CNG Cylinder Pods

These pods would be filled with CNG & then placed on the metal frame of the truck to perform dynamometer testing before the vehicle was upfitted with the permanent body and/or cylinder assembly.

Simplex Refurbished Compressor, Priority/Sequential Panel & Stacked ASME’s

This system provided the solution for Mack to expand their production of CNG trucks at the Macungie facility until we relocated it with another compressor to provide redundancy for their operations.

New Compressor with original package relocated with CNG cylinder pods to the right of the photo

The project manager from Mack, initially intended to only purchase a new compressor. After meeting with their engineering team, we suggested keeping the asset they already own (CNG package form 2012) and let us integrate the existing equipment with the new compressor. The project has been a huge success and is adjacent to their final testing facility to meet their quality control protocol (see grey building in rear of photo).

New York Specialty Projects

HYDROGEN & METHANE FUELING SYSTEM

In 2003 Air & Gas Tech designed and installed a methane detection system and HVAC upgrades for the fleet’s repair garage. This allows bus mechanics to work on vehicles safely. Our relationship with this customer continued in a service capacity for their existing station. In 2016 after Hurricane Sandy flooded the area and adversely impacted the stainless tubing, which was uncoated, we were contracted to excavate and install thermoplastic coated stainless steel below grade. In 2019 the school district invested in a new Duplex Compressor System, which we installed and retrofitted to their existing system. During the retrofit, we provided a rental compressor to keep fuel flowing. In 2021 Air & Gas Tech was contracted to upgrade the remaining CNG equipment which included a new Priority Valve Panel, Fast Fill Dispenser, and 32 new time fill hose assemblies.

Click on any photo to see a large slideshow.

Dispenser System allows for Blending Hydrogen & Methane per Programming Parameters

These units have the ability to dispenser all hydrogen or methane or any blended percentage of both based upon how the programming is set up.

CNG Compressor assembly with High Pressure Dryer Assembly

Accepts methane gas from the local utility pipeline and compresses it into the ASME cylinders for dispensing.

High Pressure Stainless Tubing & Respective Valve Panels

These panels accept the two different gases, and the valve panel is actuated by the programming of the dispense to feed the prescribed blend of gas to the vehicle.

Maine SPecialty Projects

North Atlantic Alternative Energy Advisors

In 2018, AGT designed and built a mobile fueling system for mobile CNG tube trailers, which included a priority-sequential panel, PLC/HMI, software to optimize fueling to allow temperature compensation and fuel management. In addition, all transactions are recorded and transferred to the office via the cellular device for customer billing.

Duplex CNG Compressor System with Discharge Dryers, ASME Sphere & Duplex Dispensers with Card Readers.

California Specialty Projects

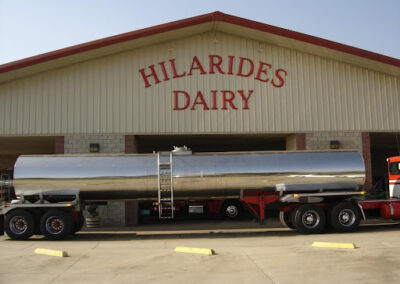

Hilarides Dairy Farm, Lindsay, Ca. Phase 3

We participated in implementing a manure to bio-gas clean-up system and respective CNG stations designed to provide methane for ten electric generators, boilers for the milk processing plant, and CNG to displace over 600 diesel gallons of fuel per day.

Click on any photo to see a large slideshow.

Boi-Gas System Provided Methane to Eliminate 600 Gallons of Diesel per Day

This project provided enough methane to operate six to eight loads of milk per day and eliminated over 600 diesel gallons by using CNG. In addition, the project generated all the electricity needed for the processing plant, hot water and the remainder of the farm’s power needs – plus sold excess to the grid.

Lagoons

Manure was collected in lagoons and hydrains flushed the area & pumped residual to separation ponds.

Separation Ponds (example of typical pond)

The manure is pumped into ponds where the solids separate out and get pumped over to a second & third pond for further separate and capture of the methane. The methane is then piped to silos filled with “SulfaTreat” to strip-out the hydrogen-sulfides from the methane, then pressurized to supplemental separation system to polish the methane to pipeline quality specifications. From this point it is fed to the CNG compression equipment for fueling tractors, Caterpillar generators, boilers for hot water processing and general gas purposes.

Booster Compressor & Clean-Up System

Our compressor is in front of the truck with 6 ASME cylinder in the rear of the building and a dispenser to the left of the pick-up truck. Sorry that this truck is in the middle of the project, however there was a time restraint to complete the project when the photo was taken.

Louisiana Specialty Projects

Cornerstone – St. Landry, LA

We partnered with Cornerstone to develop a CNG station in conjunction with their landfill gas clean-up system. This was listed as a small-scale prototype development project to yield “proof of concept” for smaller module clean-up systems. The project’s success ultimately generated 250 gasoline gallon equivalent (GGE) of CNG per day while mitigating methane leaching into the atmosphere. The results were significant air quality benefits and unique environmental education opportunities for the local community.

Click on any photo to see a large slideshow.

Connecticut Specialty Projects

Enviro Express Bridgeport, CT

Designed and built a combination LCNG station for a customer with a fleet of class 8 tractors. This included the site development, permitting, electrical, piping, infrared detection system, gas compressor, dual dispensers (LNG & CNG), fuel management credit card unit, mercaptan injection unit, and all ancillary components.

Click on any photo to see a large slideshow.

Sequential Panel & Booster System

Modular Approach (better subtitle here?)

Need Text Here

Click on any photo to see a large slideshow.